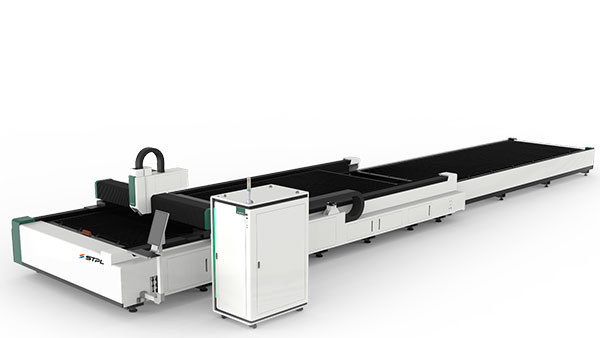

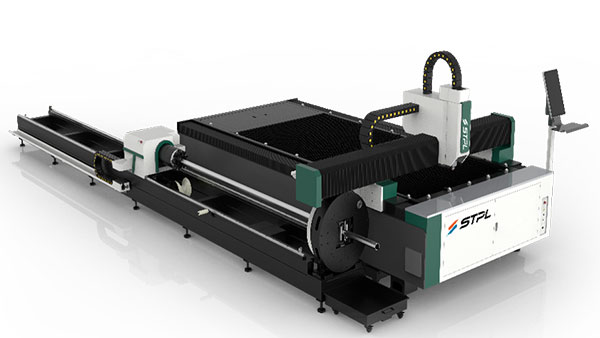

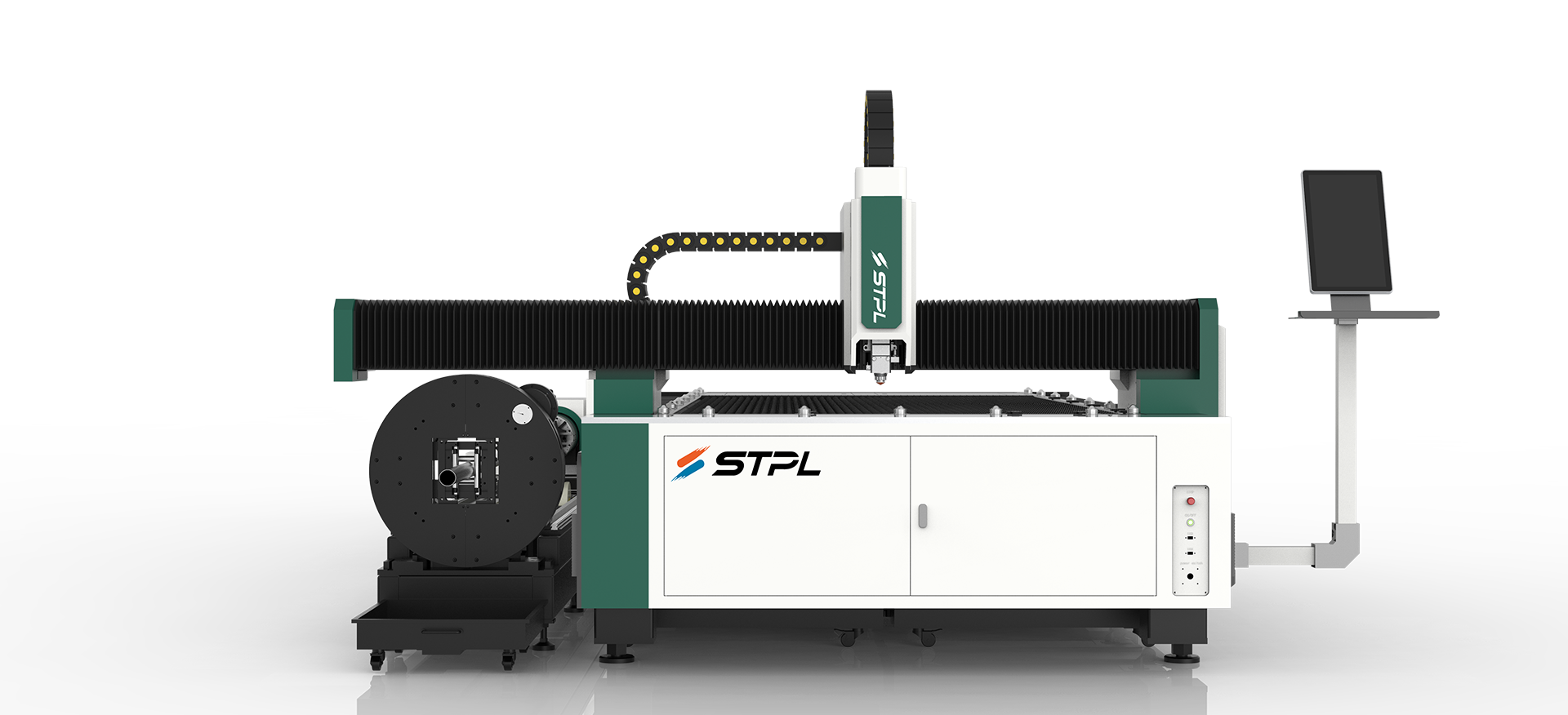

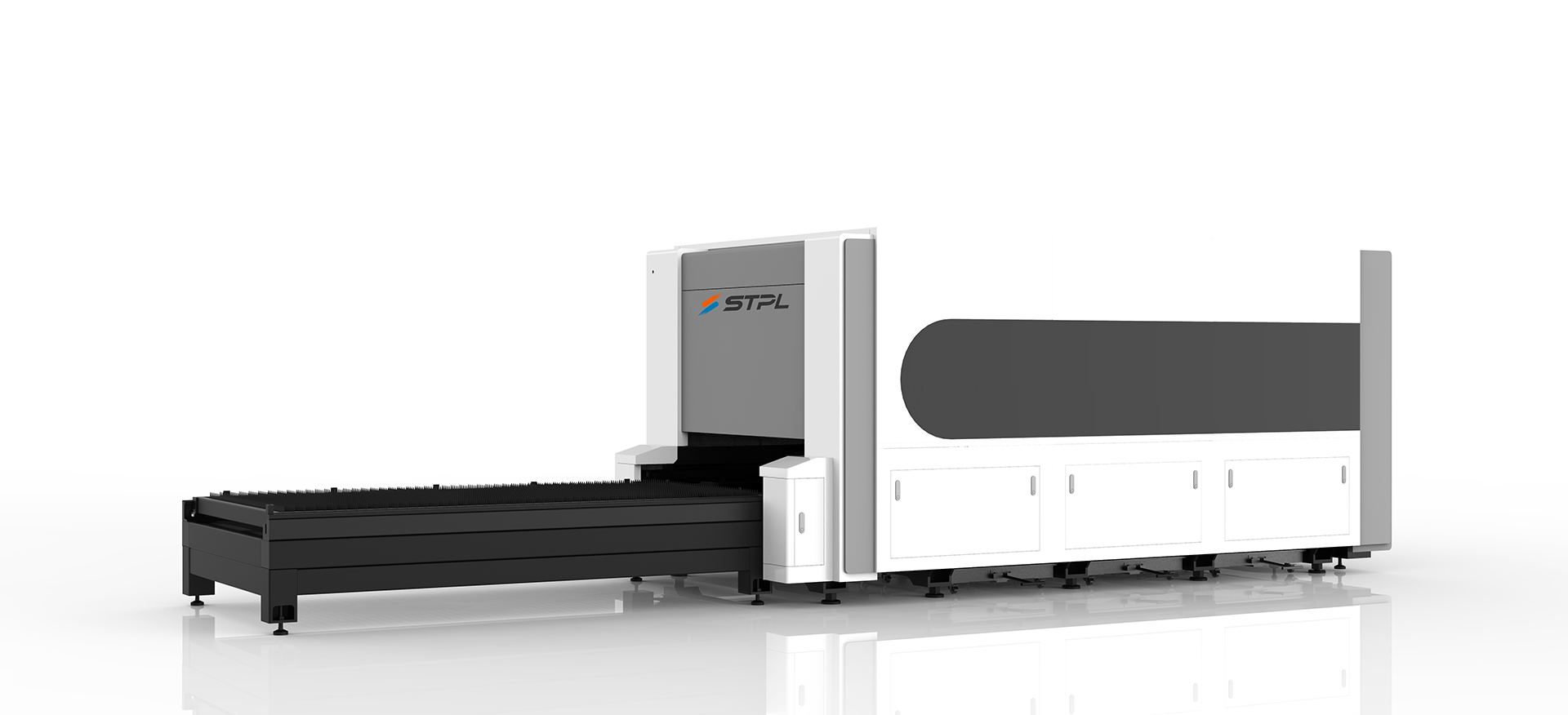

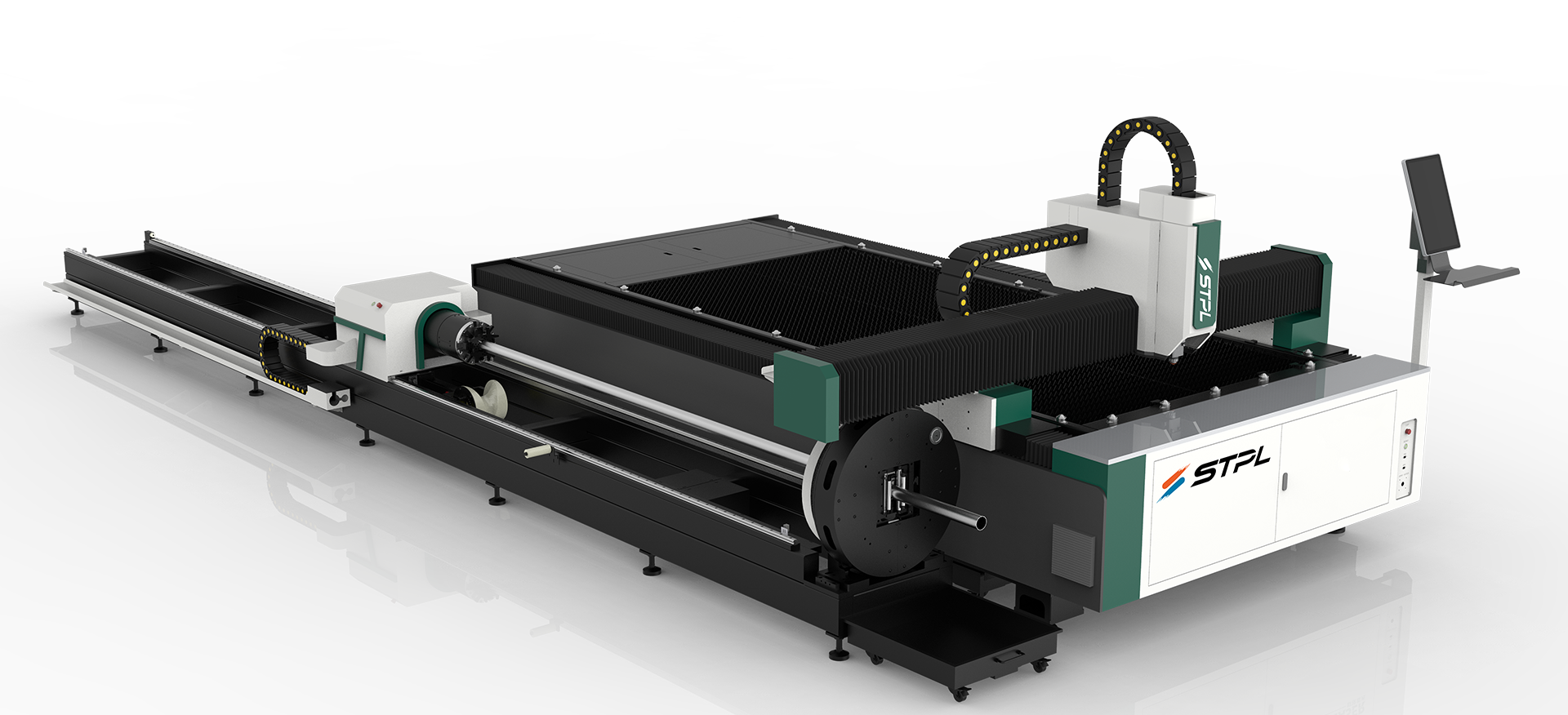

In the intricate world of precision manufacturing, the operation of a fiber laser cutting machine plays a pivotal role in determining the efficiency, productivity, and overall longevity of the equipment. STPL Industrial Laser, a leading provider of cutting-edge solutions, presents this comprehensive guide to equip operators and businesses with valuable insights into optimizing the operation of fiber laser cutting machines. From routine maintenance to parameter optimization, this guide explores essential tips to ensure both the longevity and efficiency of your STPL fiber laser machine.

Understanding the Importance of Proper Operation

Operating a fiber laser cutting machine is not merely about initiating a cutting process; it’s a nuanced practice that involves a combination of skill, knowledge, and adherence to best practices. The efficiency of the operation directly impacts the machine’s longevity, the quality of the cuts, and the overall cost-effectiveness of the manufacturing process. STPL Industrial Laser recognizes the significance of proper machine operation and offers this guide as a resource to empower operators and businesses with the tools they need to maximize the potential of their fiber laser cutting machines.

1. Preventive Maintenance: The Foundation of Longevity

At the core of efficient machine operation lies a robust preventive maintenance routine. Regular checks and timely maintenance not only prolong the lifespan of the fiber laser cutting machine but also contribute to consistent and reliable performance. STPL’s machines are engineered for durability, and a proactive approach to maintenance ensures that the equipment operates optimally over the long term.

Routine Checks

Laser Source: Regularly inspect the laser source for any signs of wear, contamination, or degradation. STPL’s machines often come equipped with advanced laser sources, and routine checks ensure the continued efficiency of the cutting process.

Optical Components: Inspect and clean optical components, such as lenses and mirrors, to maintain the integrity of the laser beam. Cleanliness is crucial for precise cutting, and STPL’s machines are designed for ease of maintenance in this regard.

Lubrication

Ensure that all moving parts are adequately lubricated. Proper lubrication minimizes friction, reducing wear and tear on components. STPL’s machines are designed with durability in mind, and regular lubrication is a key factor in ensuring their longevity.

Calibration

Periodically calibrate the machine to maintain accurate cutting dimensions. STPL Industrial Laser provides calibration guidelines for its machines, ensuring that operators can maintain the desired level of precision.

2. Optimizing Cutting Parameters: Precision in Every Cut

The efficiency and precision of a fiber laser cutting machine depend significantly on the cutting parameters selected. STPL’s machines offer a range of customizable parameters to cater to various materials and thicknesses. Optimizing these parameters is crucial for achieving the desired cut quality while maximizing efficiency.

Material-Specific Parameters

STPL’s machines provide the flexibility to adjust cutting parameters based on the specific material being processed. Understanding the material characteristics and selecting appropriate parameters is essential for achieving optimal results.

Thickness and Speed Settings

Striking the right balance between cutting speed and thickness is key. Adjusting the speed and thickness settings according to the material being processed ensures efficient cuts without compromising quality. STPL’s machines offer a user-friendly interface for easy adjustment of these parameters.

Piercing and Lead-in/Lead-out

Properly configuring piercing and lead-in/lead-out settings is essential for reducing stress on the material and achieving clean, precise cuts. STPL’s machines provide options for customization in these areas, allowing operators to adapt the cutting process to specific requirements.

3. Cleaning and Calibration: Maintaining Optimal Performance

Regular cleaning and calibration are crucial components of effective machine operation. STPL’s fiber laser cutting machines are designed with user-friendly interfaces, making these tasks straightforward for operators.

Cleaning Procedures

Laser Head: Keep the laser head clean and free from debris. Regularly inspect and clean the nozzle to ensure an unobstructed path for the laser beam. STPL’s machines often come with features that facilitate easy access for cleaning purposes.

Calibration Guidelines

Follow STPL’s calibration guidelines meticulously to maintain accurate cutting dimensions. Regular calibration is essential for achieving precise cuts consistently. STPL provides comprehensive documentation to guide operators through the calibration process.

4. Handling and Safety Practices: Ensuring Operator Well-being

Efficient machine operation goes hand in hand with proper handling and adherence to safety practices. STPL Industrial Laser places a strong emphasis on operator safety and provides guidelines to ensure safe and effective machine operation.

Operator Training

Ensure that operators undergo thorough training on the safe and efficient operation of the fiber laser cutting machine. STPL offers training programs to equip operators with the knowledge and skills needed for optimal machine utilization.

Safety Features

Familiarize operators with the safety features of the machine. STPL’s machines are equipped with advanced safety mechanisms to protect operators and prevent accidents. Regular checks ensure that these safety features are functioning correctly.

5. Software Updates and Upgrades: Staying Current with Technology

The software driving a fiber laser cutting machine plays a critical role in its performance. Regular updates and, when applicable, upgrades are essential to stay current with technological advancements. STPL Industrial Laser provides software updates and, in some cases, opportunities for software upgrades to enhance the capabilities of its machines.

Firmware Updates

Stay informed about firmware updates released by STPL. These updates often include optimizations and improvements to the machine’s performance. Regularly updating the firmware ensures that the machine benefits from the latest enhancements.

Upgrade Options

Explore upgrade options provided by STPL. Upgrading the software can unlock new features and capabilities, enhancing the overall functionality of the machine. STPL’s commitment to technological advancement ensures that its machines can evolve with the changing needs of the industry.

Conclusion

In conclusion, operating a fiber laser cutting machine efficiently and ensuring its longevity requires a holistic approach. STPL Industrial Laser, with its commitment to precision, durability, and customer support, provides the foundation for operators and businesses to maximize the potential of their fiber laser machines. From routine maintenance to parameter optimization and safety practices, the tips outlined in this guide serve as a comprehensive resource for those seeking to achieve excellence in their manufacturing processes.

Remember, operating a fiber laser cutting machine is not just about initiating cuts; it’s about harnessing the full potential of a sophisticated piece of technology. With STPL’s guidance and commitment to excellence, operators can navigate the intricacies of machine operation with confidence, unlocking the full spectrum of possibilities that fiber laser cutting technology has to offer.